- Home

- Products

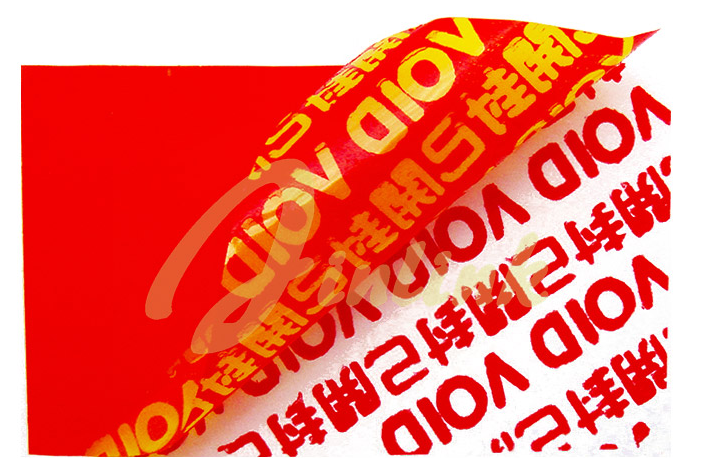

- Tamper Evident Void Label Material

- Ultra Destructible Vinyl Material

- Tamper Evident Security Tape

- Hologram Sticker

- Tamper Evident Security Bag

- Latest Products

- About Us

- Contact Us

Precautions for Anti-tamper Security VOID label printing and plate making: The printed parts of flexographic printing are mainly based on the field, lines, texts, etc. Most of the printing materials used are paper, aluminum foil, plastic film, stickers and so on. When printing an absorbent substrate with a water-soluble or solvent-based ink, the infrared hot air drying effect causes the material to be pumped up, which affects the overprinting accuracy. Therefore, care should be taken when considering the printing color sequence to avoid such problems.

Label printing plates contain large-area color plates of Tamper Proof Security Material that should be printed as far as possible in the rear unit, because the substrate absorbs a large amount of ink and then infrared drying, the pumping change of the solid unit is naturally larger than other units. Some have a greater impact on the overprinting process during the printing process. If such a unit is printed after text or lines, it will have a certain positive impact on overprinting. If it is necessary to print the solid part in the front color group, you can consciously increase the compensation in the up and down direction slightly to compensate for the loss caused by the pumping up, making the overprint more accurate.